Print your vision

Embark on the Inkfinity Experience with us - let's collaborate to ensure your next project becomes a print sensation!

About Inkfinity Solutions

Turning ideas into reality

Welcome to Inkfinity Printing Solutions, Abu Dhabi's go-to destination for transforming your vision into reality! With a wealth of experience spanning 15 years, we take pride in showcasing our expertise and delivering exceptional results.

Nestled in the vibrant Musafa district of Abu Dhabi, our printing professionals are dedicated to surpassing your expectations and delivering outstanding outcomes.

At Inkfinity, we firmly believe that every print should weave a compelling narrative, evoke emotions, and leave a lasting impact. As pioneers in print solutions, we specialize in producing high-quality, visually striking prints that go above and beyond. Rest assured; our cutting-edge technology is here to bring your boldest ideas to life.

Our Mission

Our mission is simple yet powerful - to exceed expectations with every print. We strive to provide exceptional value through innovative technologies, exceptional customer service, and a steadfast commitment to environmental sustainability.

Our Vision

With a vision to lead the printing industry, we are dedicated to continuously evolving, adapting to our clients' changing needs, and setting new benchmarks in the field. Count on Inkfinity Printing Solutions to bring your concepts to life with precision and style.

Inkfinity Solutions & Services

Services we offer

Your one-stop shop for all things print!

Offset Printing

Offset printing is a popular and widely-used technique that involves transferring an inked image from a metal plate to a rubber blanket onto the printing surface. In this process, the picture is first etched onto a metal plate, usually made of aluminum. This plate is then inked, and the inked image is transferred onto a rubber blanket before finally being applied to the desired printing surface, typically paper.

One of offset printing's key advantages is its ability to produce high-quality and consistent prints in large quantities. This method is particularly well-suited for large print runs where image quality, detail, and color accuracy are crucial. Offset printing is commonly used to produce various printed materials such as books, newspapers, magazines, brochures, and more.

Offset printing is preferred for its cost-effectiveness, making it an excellent choice for high-volume printing jobs. Its ability to produce sharp, detailed prints with accurate color reproduction makes it a go-to option for many businesses and industries requiring large-scale printed materials.

Read More

Read Less

Packaging

Packaging in the printing business refers to the creation of printed materials used to enclose, protect, and present products. It plays a crucial role in marketing, branding, and protecting goods during storage and transportation. It also serves as a communication tool for conveying important information to consumers.

In the printing business, packaging can involve a variety of printed materials, including:

Labels and stickers These provide branding, product information, and regulatory details on food products, beverages, cosmetics, and more.

Folding cartons These are printed, pre-cut, and creased paperboard containers that are folded and formed into packaging for products like cosmetics, pharmaceuticals, electronics, and more.

Corrugated boxes These are sturdy and durable cardboard boxes used for shipping and storing products of various sizes and shapes.

Flexible packaging This includes pouches, bags, and wrappers made from materials like plastic film, aluminum foil, or paper. It is commonly used for food, snacks, and personal care products.

Shrink sleeves These labels are applied around containers and shrink to conform to the shape of the package when heat is applied. Shrink sleeves provide additional branding space and a 360-degree display area.

Packaging in the printing business often involves using advanced printing techniques, such as digital printing, flexography, offset printing, and gravure printing, to achieve high-quality, visually appealing, and durable printed materials. The design, quality, and functionality of packaging can significantly impact a consumer's purchasing decision and brand perception

Read More

Read Less

UV Effects Digital Printing

UV Effects Digital Printing is a specialized printing technique that utilizes ultraviolet (UV) light to cure or dry the ink on the printed surface instantly. This process involves using UV-curable inks exposed to UV light to create a chemical reaction that quickly hardens the ink.

UV Effects Digital Printing offers several advantages over traditional printing methods, such as:

Faster production times The instantaneous curing of ink with UV light allows for quicker turnaround times as there is no need for drying time between printing and finishing.

Improved print quality UV-curable inks produce vibrant colors and sharp images due to the quick curing process, resulting in high-quality prints with fine details.

Durability UV-curable inks create a more durable and scratch-resistant print, making UV Effects Digital Printing ideal for applications where the printed material may be worn and torn.

Environmentally friendly UV Effects Digital Printing is considered eco-friendly as the inks contain fewer volatile organic compounds (VOCs), and the curing process reduces emissions compared to traditional solvent-based inks.

UV Effects Digital Printing is commonly used for signage, point-of-purchase displays, packaging, labels, and other applications where print quality, durability, and quick production times are essential.

Read More

Read Less

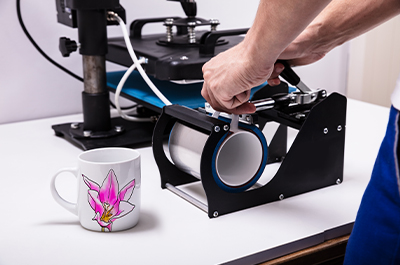

Digital printing

Digital printing is a modern printing method in which digital-based images are printed directly onto a variety of media surfaces, such as paper, cardstock, canvas, fabric, and more. It differs from traditional printing techniques like offset printing, which involves creating plates, screens, or cylinders for each print job.

In digital printing, the image is sent directly from a computer to the printing device, eliminating the need for intermediate steps. The printer processes the digital file, which applies ink or toner directly to the substrate in a single pass. This process is quick, efficient, and cost-effective for small to medium print runs.

Digital printing offers several advantages, including:

Customization Digital printing allows for variable data printing, meaning each printed piece can be customized with unique text, images, or graphics. This is ideal for personalized marketing materials, such as direct mail campaigns or promotional items.

Quick turnaround Digital printing eliminates the need for printing plates, reducing setup time and enabling faster turnaround times compared to traditional printing methods.

Cost-effective for short print runs Digital printing is cost-effective for small print quantities because there are no setup costs associated with plates or screens. This makes it a preferred option for on-demand printing.

High-quality prints Digital printing technology has advanced to produce high-resolution prints with vibrant colors and sharp detail, making it suitable for various applications.

Digital printing is commonly used for brochures, flyers, business cards, posters, labels, packaging, and other marketing materials where customization, quick turnaround, and high-quality prints are essential.

Read More

Read Less

Binding and finishing

Binding and finishing in the printing business refers to the processes that transform printed sheets into a final, complete product. These processes involve various techniques and methods to bind, or finish printed materials, enhancing their appearance, functionality, and durability.

Some standard binding and finishing processes in the printing industry include:

Folding Folding involves creasing and folding printed sheets into a specific layout or format. It is commonly used for creating brochures, leaflets, and other multi-page documents.

Binding Binding refers to the methods used to secure and hold together the pages of a printed document. Standard binding methods include saddle stitching, perfect binding, wire binding, spiral binding, and comb binding.

Cutting and trimming Cutting and trimming processes trim printed sheets to the desired size and shape. These processes ensure uniformity and precision in the final printed product.

Laminating Laminating involves applying a thin layer of plastic film to the surface of printed materials to protect against wear and tear, moisture, and UV exposure. It also enhances the appearance and durability of printed items.

Coating Coating involves applying a protective or decorative coating to printed materials. Standard coatings include gloss, matte, and satin finishes that enhance the visual appeal and durability of the printed product.

Embossing and debossingEmbossing and debossing are techniques used to create raised or recessed designs on printed materials. These processes add texture and visual interest to branded materials like business cards, stationery, and packaging.

Die-cutting Die-cutting involves cutting printed materials into custom shapes or designs using a die or cutting tool. It is commonly used to create unique packaging, promotional materials, and marketing collateral.

Binding and finishing processes are critical to the overall quality and presentation of printed materials. These processes help create professional, polished, and functional print products that meet clients' and end-users' specific requirements and expectations.

Read More

Read Less

Our clients

Inkfinity – bringing your ideas to life

Join the

Inkfinity Experience!

Contact us today to discuss your printing needs and let us exceed your expectations!

Contact information

Embark on the Inkfinity Experience

Contact us and let's collaborate to ensure your next project becomes a print sensation!